Access to water is crucial for maintaining health, sanitation, and sustaining various essential activities. Catering to these demands are water pumps, the heart of fluid management systems that ensure the reliable and efficient distribution of water.

Modern water pumps are the heartbeat of countless applications, ranging from agricultural irrigation to industrial processes and residential water supply. These machines can efficiently move water, ensuring it reaches its intended destination with optimal pressure and volume.

This comprehensive guide explores the different types of water pump machines and how each works, highlighting their distinctions and guiding you in choosing the best one for years of efficient service.

Exploring the Different Types of Water Pumps

Water pumps come in various types, each tailored to specific applications based on their design and functionality.

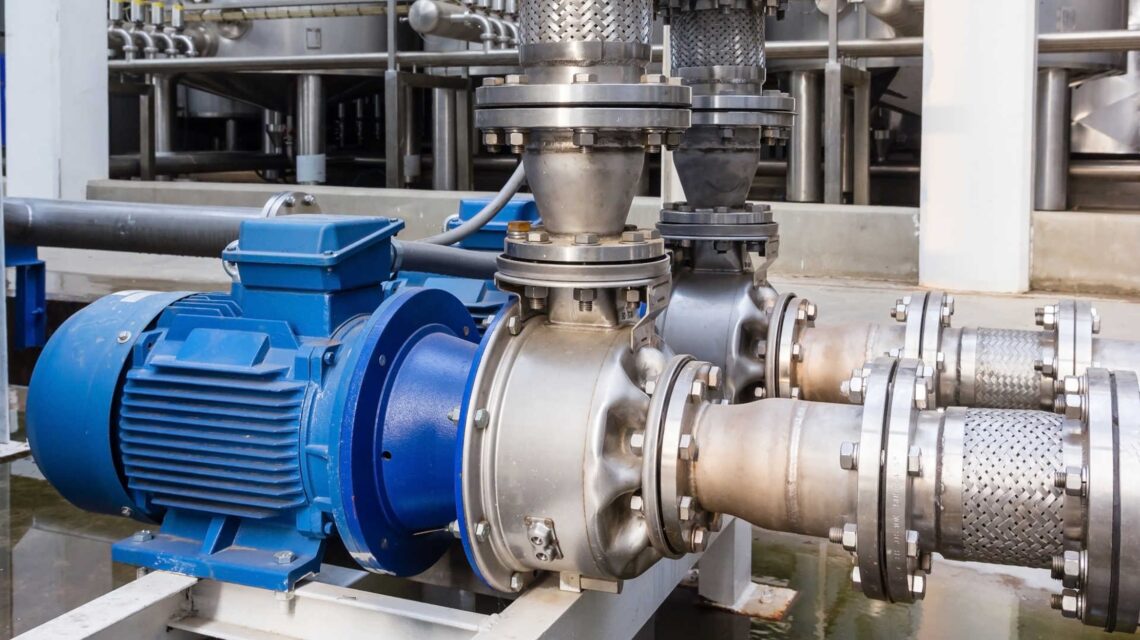

Centrifugal Pumps

Centrifugal pumps have extensive scope in various industries due to their inherent simplicity and versatility in fluid transfer applications. These machines convert rotational energy from an impeller into kinetic energy, efficiently generating a continuous water delivery.

A centrifugal pump’s design is ideal for high flow rates and moderate pressure applications. These functions cover water supply, wastewater treatment, irrigation, and industrial processes.

The widespread use of centrifugal pumps underscores their reliability and effectiveness in meeting the diverse needs of modern-day water management and industrial systems.

Submersible Pump

Submersible pumps, engineered to operate whilst submerged in water, offer versatile and efficient solutions. These machines are well-suited for extracting water from deep wells and submerged sources.

These pumps showcase a hermetically sealed motor tightly coupled to the pump body, ensuring optimal performance even in submerged conditions. This unique ability allows the equipment to cater to domestic water and agricultural irrigation needs.

Diaphragm Pumps

Diaphragm pumps, employing a flexible diaphragm for pumping action, are pivotal in applications demanding precise fluid control. These demanding tasks include chemical processes and water treatment.

Renowned for their accuracy, diaphragm-type pumps feature a seal-tight design, making them ideal for preventing cross-contamination and ensuring the controlled transfer of sensitive fluids.

A diaphragm pump machine’s versatility shines in handling abrasive or viscous substances without compromising efficiency. The availability of diverse diaphragm materials enhances compatibility with various chemicals.

Piston Pumps

Piston pumps use reciprocating pistons for fluid movement, offering dynamic and robust technology with varying applications. The machine follows a back-and-forth motion of pistons within cylinders, generating high-pressure flows.

The resulting powerful flow makes piston types particularly well-suited for car washes, pressure washers, and other industrial processes that demand precision and high pressure.

The adaptability of piston pumps, coupled with their ability to handle challenging conditions, underscores their significance in powering diverse high-pressure applications.

Selecting the appropriate water pump is crucial to ensure optimal performance and longevity.

Your choice of water pump should depend on these factors.

How to Choose the Right Water Pump

Purpose of Use

Identify the specific application, whether it’s for residential water supply, agricultural irrigation, or industrial processes.

Flow Rate and Pressure Requirements

Determine the required flow rate and pressure for your site requirement. For instance, centrifugal pumps are excellent for high flow rates, while piston pumps are suitable for high-pressure applications.

Power Source

Consider the available power sources: electric, solar, or engine-driven. Your choice of water pump should be compatible with your site’s power supply.

Installation and Space Constraints

Evaluate the available space for pump installation and any spatial limitations. For instance, submersibles are ideal for compact spaces, whilst centrifugal pumps may require more room.

Material Compatibility

Ensure the pump materials are compatible with the type of fluid. If you’re pumping chemicals in addition to water, the machine’s materials should resist corrosion or degradation.

Maintenance Requirements

Consider the level of maintenance the pump requires. Submersibles, for instance, are often easier to maintain due to their enclosed design, whilst centrifugal pumps may require more frequent inspections.

Aside from choosing the best pumps for your needs, you must know the proper installation steps before use.

Installation and Setup Guidelines

Positioning and Alignment

Position the pump correctly to ensure proper water intake and discharge.

Align the pump with the plumbing system to minimise stress on the components.

Secure Mounting

Ensure the pump is securely mounted on a stable foundation to reduce vibrations and prevent unnecessary movement during operation.

Check Seals and Connections

Inspect seals and connections for any signs of leaks. Make the connections as tight as needed and replace seals if they show wear or damage.

Prime the Pump

If installing centrifugal pumps, you must ensure proper priming before operation. Priming is essential to remove air from the system and facilitate smooth pumping.

Test Run and Adjustments

Perform a test run after installation to check for any issues and adjust the pump’s settings or components based on the test results.

Follow these water pump maintenance guidelines to ensure years of reliable service.

Maintenance Tips for Longevity

- Perform routine checks on the pump, examining for any signs of wear, leaks, or unusual noises.

- Keep moving parts well-lubricated to reduce friction and enhance efficiency.

- Clean intake screens and filters to prevent clogs, ensuring a steady flow.

- Understanding the importance of modern water pumps and the different types available is essential for making informed decisions.

By choosing the right pump and implementing proper maintenance practices, you can maximise efficiency and ensure the longevity of your water pump. Whether for agricultural, industrial, or residential purposes, use this article as your go-to resource for unlocking the potential of water pumps.